Betech Mass Turning from Hoogeveen is very proud of her new order. In the coming years she will manufacture parts for a newest electric Mercedes.

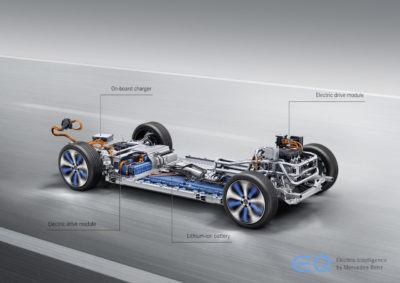

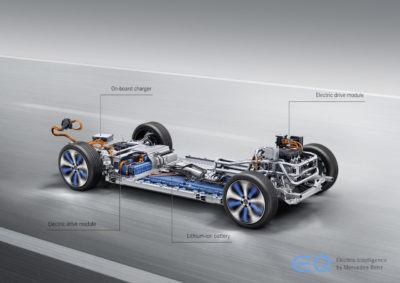

The car manufacturer will be on the market next year with the electric variant, the Mercedes EQC. “We have already made the first products”, says Wim van de Beld (CEO) in the TV Drenthe program ‘Doing business in Drenthe’. “There are about six kilos of parts of us in that car, such as parts for suspending the electric motor in the chassis.”

Completely automated

The headquarters of the Betech Group is located in Hoogeveen. The company also has manufacturing locations in Groningen and Steenwijk. In order to be able to execute this order, Van de Beld makes considerable investments. “It’s a multi-million order, at least until 2028. That also requires more people, but also more robots and automated production lines.” New machines are purchased for this order.

Betech Mass Turning does not deliver the parts directly to Mercedes, but to a Tier 1 supplier. Nevertheless, the German brand does want to know how everything about production is in Hoogeveen. For that they come to take a look in Hoogeveen. “Such a customer wants to see our production and they want a real time and online view of our manufacturing process, when we replace a tool and when the series is about ready. We’re working very hard to achieve this.”

Expansion in Hoogeveen, Groningen and Steenwijk

Betech Mass Turning has just built new productions halls in Hoogeveen. This means that the area on commercial premises has doubled to around 10,000 square meters. Van de Beld also has plans to expand the production locations in Groningen and Steenwijk. “We are also going to double Groningen and Steenwijk. At this moment the whole Betech Group is just flourishing: the bigger you are, the better you’re able to automate, the more important you become in the market.”